Precision Machining

Constantly updating its facilities and its tools Paesi has advanced equipment for machining parts with quality and precision combined with lower production times and therefore better costs.

Discover our solutions >>Constantly updating its facilities and its tools Paesi has advanced equipment for machining parts with quality and precision combined with lower production times and therefore better costs.

Discover our solutions >>Av. João Alberto, 895, Bairro Vicentina São Leopoldo - RS

Map in google maps >> (51) 3589.6852 / 3589.8689

By means of CNC machinery with driven tool and oriented plate, we manufacture parts involving simultaneous precision turning and milling in a single process, ensuring better quality, shorter preparing and production times, thus ensuring lower cost for production of serial and non-serial complex parts.

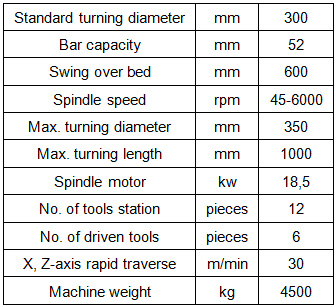

Check out the specifications of CNC Lathe FEELER FTC350 XL:

Solid-works CAM programming, Fanuc control with CNC Feeder and oriented board.

We seek to be always updated on the selection and use of appropriate and high-tech tools. We work with inserted tools selected together with suppliers who provide the technical support and updates.

The use of four axes enables higher quality of machining and dimensional accuracy in performing complex parts involving turning, milling, drilling, and threading, joining processes in a single machine, reducing the number of machines to be prepared, preset time, and increasing the machining accuracy.

The oriented board allows to perform front and side angled milling and drilling operations accurately.

Programming and machining simulation performed in Solid-Works and CAM systems.

The CNC feed system allows serial machining of large batches with less downtime and better use of material.

High speed machining

Great quality machining

Lower production costs

Agility in preparing and programming

Lower downtime

Better use of material

High dimensional accuracy

Reduced preset and quantity of machines

Conheça alguns estudos de caso relacionados a este equipamento:

The axis is responsible for tire traction and expansion in manufacturing thereto. The parallelism variation of the axis and, in particular, of the knurled can displace or expel the tire from the machine.

If you have a specific need within the area of industrial machining, report in the form below so we can assist you:

Stay informed on our latest news!